Destaques Embraco

-

10 de dezembro de 2020

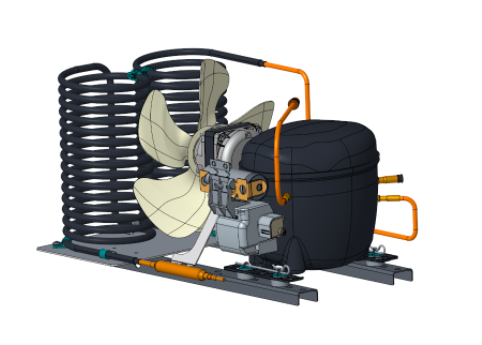

10 de dezembro de 2020Entenda como instalar as unidades condensadoras Embraco

-

10 de dezembro de 2020

10 de dezembro de 2020Embraco apresenta novo compressor de velocidade variável em R290 altamente eficiente

-

01 de junho de 2021

01 de junho de 2021Como selecionar o compressor ideal

-

-

24 de novembro de 2021

COMPRESSORES DE VELOCIDADE VARIÁVEL SÃO O CAMINHO PARA A ECONOMIA DE ENERGIA NA REFRIGERAÇÃO

-

31 de agosto de 2021

5 tendências para o futuro do mercado da refrigeração

-

06 de março de 2020

Melhores práticas para se trocar um compressor

-

04 de março de 2020

Vantagens ambientais e operacionais dos compressores de velocidade variável

-

10 de fevereiro de 2020

Parceria entre Embraco e Fricon estabelece um novo patamar em eficiência energética

Vídeos Embraco

Ver mais-

Vídeo umidade no Sistema de Refrigeração

Confira o vídeo sobre a umidade no sistema de refrigeração.

-

Substituição do R22 pelo R422D em alguns compressores Embraco

Saiba mais sobre substituição do R22 pelo R422D em alguns compressores Embraco.

-

Embraco Plug n’ Cool

Embraco Plug N’ Cool é um novo conceito em refrigeração.