Understand their features and the care required in their application.

The use of natural cooling fluids has been growing quickly all over the world. Among them, the hydrocarbons stand out – R600a, or isobutane; and R290, or propane.

They already had a strong presence in certain regions, especially in Europe. But, in recent years, they have been gaining space in the Brazilian market, both for their positive features, and for two other reasons:

• The gradual elimination of the substances which cause damage to the ozone layer (such as CFCs and HCFCs);

• The restrictions on cooling fluids which contribute to global warming (the case of HFCs, as shown in the box on the page at the side).

From the environmental point of view, hydrocarbons are excellent options: they do not harm the ozone layer and have a practically zero impact on global warming.

To finish, regarding the technical aspect, they have a very good performance, compared with other options of cooling fluids.

For all these reasons, Embraco considers them to be an excellent alternative and has dedicated itself to R&D of refrigeration solutions which incorporate them.

Today the company offers a wide line of compressors for R290 and R600a. Embraco’s work, however, goes much beyond this. First, as a leading company in technology, it contributes to influencing the market in the direction of use of this alternative. Many people who are not familiar with these substances have the following line of thought: “If Embraco recommends it, it is a good solution”.

The direct performance of the company in the market also brings concrete results: it provides all the technical support to OEMs of refrigeration systems – household and commercial – interested in adopting the use of isobutane or propane.

Clearly, the refrigeration technicians were not forgotten in this process of making hydrocarbons better known. Embraco has produced various technical material and disclosed information concerning these cooling fluids.

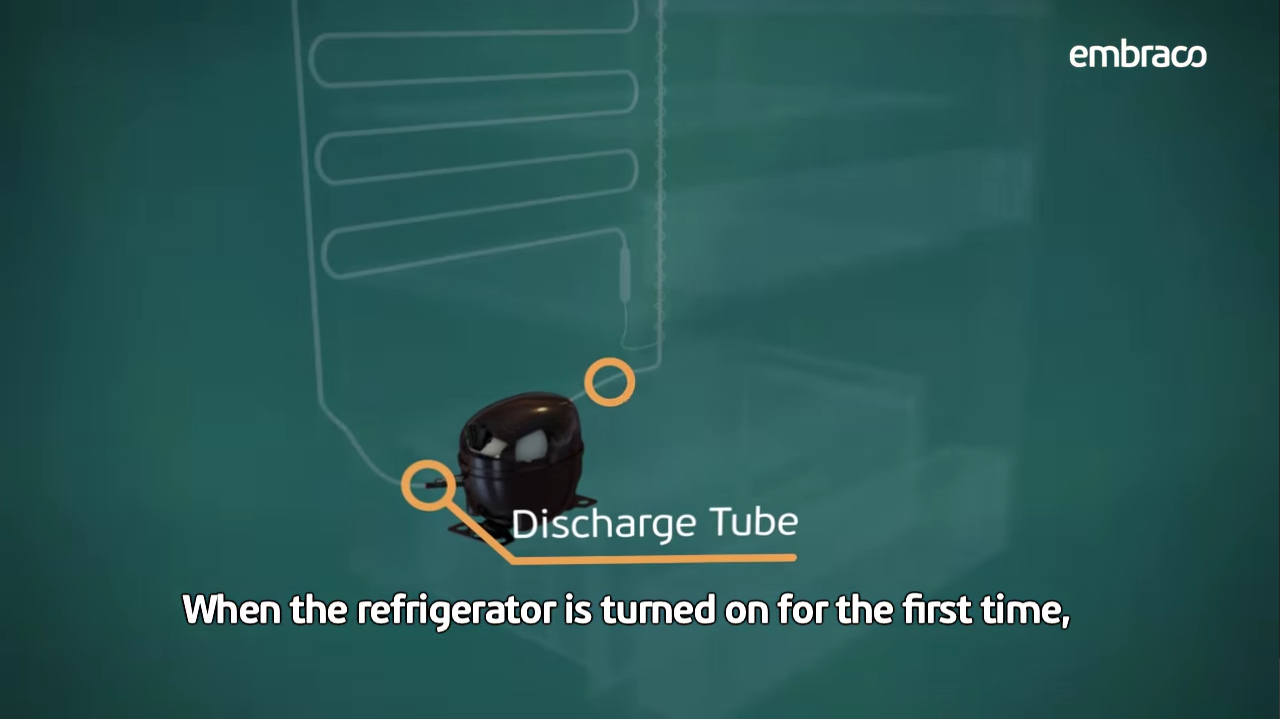

An example was the update done in compressor exchange video, to include this subject.

On the pages of the magazine, these professionals are also frequently looked at, in material which concerns various technical aspects. Especially, we have emphasized that there is no reason to fear these substances, which frighten those who do not know them because they are inflammable.

As we have already said in previous editions, their use is safe, otherwise countries such as Germany and France – which have very advanced legislation for protecting people and the environment – would not approve them. It suffices to know two facts to remove this fear:

• The electrical circuit of the equipment which incorporates them is designed to prevent the generation of sparks;

• The load of hydrocarbon in refrigerators is very small.

This last feature avoids that, if there is leakage, a significant concentration of gas occurs in the environment. In other words, R600a and R290 may be inflammable, but they do not generate risks of explosion.

Attention to the differences

As occurs with any product, it is necessary to know the specific features of hydrocarbons, in order to work in a correct and safe way.

Besides following the good practices of preventive and corrective maintenance, it is necessary to be attentive to certain aspects in which they are different, for example, than HCFCs or HFCs.

As R600a and R290 are inflammable, differentiated procedures must be adopted in the case of welding piping. In these situations, it is essential to certify that the piping is totally exempt of isobutane or propane.

The blowtorch must only be used after this, not to have risks. An essential measure for safety is to pass a load of nitrogen in the piping, to leave it without remains of gas.

Another important tip, in the case of exchanging the compressor: the isobutane or propane of the system can be collected in a closed container. Differently than occurs with other substances, hydrocarbons can also be released in a well-ventilated environment (it is allowed to do this, because they do not cause damage to the ozone layer or have an impact on global warming).

It should be borne in mind also that, instead of welding, it is possible to opt, with total safety, for using the Lokring system, which avoids the requirement of blowtorch.

Regarding the gas load, it is important to know that the quantities are smaller than those of other cooling fluids. Other procedures are similar. Read + about it.

The filter dryers are another aspect that deserves attention: in hydrocarbon systems only those which contain desiccant 4A-XH5 must be used.

Another feature that should be observed concerns the electric components: only the ones which have features appropriate to inflammability of these cooling fluids can be used. There is no room, therefore, for improvisations.

The differences described in the previous paragraphs show that dealing with R600a or R290 is by no means an impossible task.

Those working correctly and carefully, following the technical guidelines, will not have difficulty executing a good service.

International agreement imposes restrictions on HFCS

In October, a global agreement was signed to reduce the use of HFCs (hydrofluorocarbons). Approximately 200 countries agreed to establish restrictions on the use of these substances, which have been used as replacements of CFCs. The reason for these restrictions is the negative impact that they cause in terms of global warming.

The decision was taken at a meeting in Kigali, in Ruanda, and it complements the Protocol of Montreal, which had great success in eliminating the consumption of gases harmful to the ozone layer. The concern is justified because the use of HFCs is increasing at a rate of 10% a year and the projections indicate that, if nothing is done, the demand will continue to grow.

A commitment was established so that the use of HFCs is reduced gradually. The reduction process begins with most developed countries, which in 2019 will need to reduce this use by 10%, compared with the volume consumed between 2011 and 2013. In these countries, by 2036, the reduction will have to be 85%.

In Brazil, as in all Latin America, the process starts in 2024, when there must be a cut of 10% related to the volume used between 2020 and 2022. By 2045, the reduction will be 80%.

The agreement was considered to be an essential step in the fight against global warming, being able to result in a reduction of 0.5ºC in the temperature of the planet.