Know the main differences between them

The LST and HST acronyms are used frequently to describe compressors. But do you know what they mean? LST stands for low starting torque. In turn, HST is the acronym for high starting torque.

To make their differences clearer, below we present some motor information and characteristics that these compressors use and their application.

Compressor torque and corresponding speed

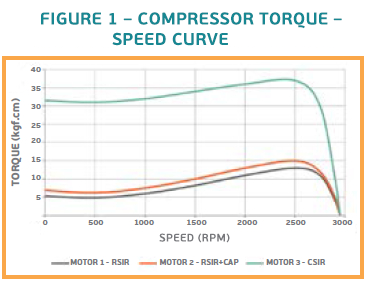

Figure 1 shows a torque curve as a function of speed for three motors that are used in compressors with similar cooling capacities.

From the start (speed equal to zero), the motor torque increases until it reaches its highest point and then begins to decrease until getting close to zero, at which point the rotor stops accelerating and the maximum speed is reached. The smaller the load, the lower the required motor torque and the greater the speed, never exceeding the synchronous speed, which is 3000 rpm (50 Hz) shown on the graph. The synchronous speed or maximum speed can be calculated by the formula Ns=60*f, where f is the frequency of the supply voltage.

Table 1 shows some information about the compressor motors. Comparing motor 1 and motor 2, it’s noted that they have the same A configuration. The only difference between them is that motor 2 uses a starting capacitor. The starting torque of motor 2 is 30% higher than the starting torque of motor 1. This is a gain provided by using the starting capacitor.

Note: The compressor motor is determined by a number of factors, including the diameter and length of the auxiliary and running coil wires, coil material, height and type of steel for motor packages, etc. Configurations A and B above refer to these factors.

In the comparison between motor 2 and motor 3, it’s noted that they have the A and B configuration, respectively, and that both use the starting capacitor. But the starting torque of motor 3 is 450% higher than the torque of motor 2 (that is, 4.5 fold). This is due to the difference between configuration A and B of the motors. Basically, the difference between the two configurations is just one: in the case of B, the motor is specifically designed for the CSIR configuration using a starting capacitor, whereas in the case of A the motor was designed specifically for the RSIR configuration, without a starting capacitor.

Understanding better the LST and HST characteristic

It’s worth remembering that the motor is one of the components used by the compressor. In turn, the classification LST and HST is a characteristic of compressors, which will be detailed below.

LST

LST compressors for having a low starting torque, only start with equalized pressures, which is a refrigerator operating condition. Therefore, they always use capillary tubes as a control element, which causes the pressure between the discharge and suction to be equalized before the compressor’s next start.

This type of compressor shouldn’t be used with an expansion valve, since it will face problems during start.

Typically LST compressors are equipped with motors having a similar torque to motor 1 or motor 2, one of the three types below:

- RSIR (Resistive Start Inductive Run);

- RSCR (Resistive Start Capacitive Run);

- PSC (Permanent Split Capacitor).

HST

HST compressors are capable of starting with non equalized pressures, that is, when the cycling time using the capillary tube is very short (less than 5 minutes) or with expansion valves. Thus, the compressors are equipped with more robust motors, with torque characteristics similar to motor 3, and are specifically designed for starting capacitor use.

The HST compressor motors are of the types CSIR (Inductive Capacitive Start Run, or CSCR (Capacitive Start Capacitive Run).

Table 2 shows an overview of the characteristics of each compressor configuration in relation to the type of start.

Inadequate torque

When the initial torque required by the cooling system during startup is greater than the torque that the compressor can deliver, there will be problems. The compressor will be energized, but the rotor won’t turn for not having enough torque. As a result, the compressor is subjected to maximum current, which is the locked rotor current. In this case, the thermal protector will actuate and turn off the compressor, preventing further damage.

For more critical starting conditions, it’s always recommended to use HST compressors.

Say no to improvising

Embraco compressors, whether LST or HST, are designed to meet various requirement and specification standards. They pass through complex tests in laboratories to ensure their optimum performance, fulfill Embraco’s quality requirements and meet safety standards. Therefore changes or improvisations aren’t recommended.

A practical example which shouldn’t be adopted is to include a starting capacitor in a LST compressor, without it being tested. The addition of a starting capacitor, as we have seen here, can increase the motor starting torque (motor 2 compared to motor 1), but it doesn’t compare to torque gain which is needed to turn a LST compressor into a HST (motor 3 compared to motor 2).

Moreover, this change doesn’t guarantee even this improvement effect, since the capacitance of the starting capacitor may be beneficent or maleficent.

Remember that for any change, extensive tests are performed, such as those made in Embraco laboratories, to ensure that the compressors always operate in the best conditions. In addition to the change in starting torque, the starting capacitor affects other compressor parameters such as current, requiring assessment of the starting relay and overload protector to ensure compliance with safety standards.

Therefore, without performing prior laboratory testing for certification, Embraco’s recommendation is: a starting capacitor should never be used to boost a LST compressor.

[box side=”alignleft” color=”box-verde” pos=”horizontal”]

Understand the concept of torque

Torque can be defined as the force applied to an object, which is used to make it rotate about an axis or center point. To calculate the torque, it’s necessary to multiply the force applied by the distance measured between the application point and the rotation axis center.

In a very simplified manner, it can be said that torque is a force that tends to rotate or turn objects. For example, the force that your hand has on a screwdriver to tighten a screw.

On compressor start, the torque is the force that the compressor has to apply to overcome the difference between low and high pressures, rotor inertia and friction among the piston, connecting rod and cylinder. In this process, and in many cases, the compressor will go from 0 to 3600 rpm (60Hz) or 0 to 3000 rpm (50Hz) in less than a second.

[/box]